In the age of personalization, UV printing has quietly become one of the most powerful tools for small businesses, makers, and storefronts that want to offer premium, fast-turnaround custom products. Whether you’re running a boutique that sells custom phone cases, launching a side hustle printing personalized gifts, or expanding a merch line, UV technology delivers crisp, durable prints across a wide range of materials — and modern compact models make entry easier than ever. In this post I’ll explain what makes UV printing special, how it stacks up against other methods, why small-form A5 and flatbed units matter, and practical tips to turn a UV printer into a reliable revenue stream.

What is UV printing — in plain terms?

UV printing uses specially formulated inks that are cured instantly by ultraviolet light as they are laid onto the substrate. That instant curing creates sharp, vibrant images that adhere well to many surfaces, from plastics and metals to glass and leather. Because the ink dries on contact, the process reduces smudging, speeds throughput, and allows for printing on rigid or oddly shaped items that would be difficult with heat- or solvent-based processes. The VergeColour Vistas

Why entrepreneurs love UV printing right now

There are three practical reasons UV printing is hot for small businesses:

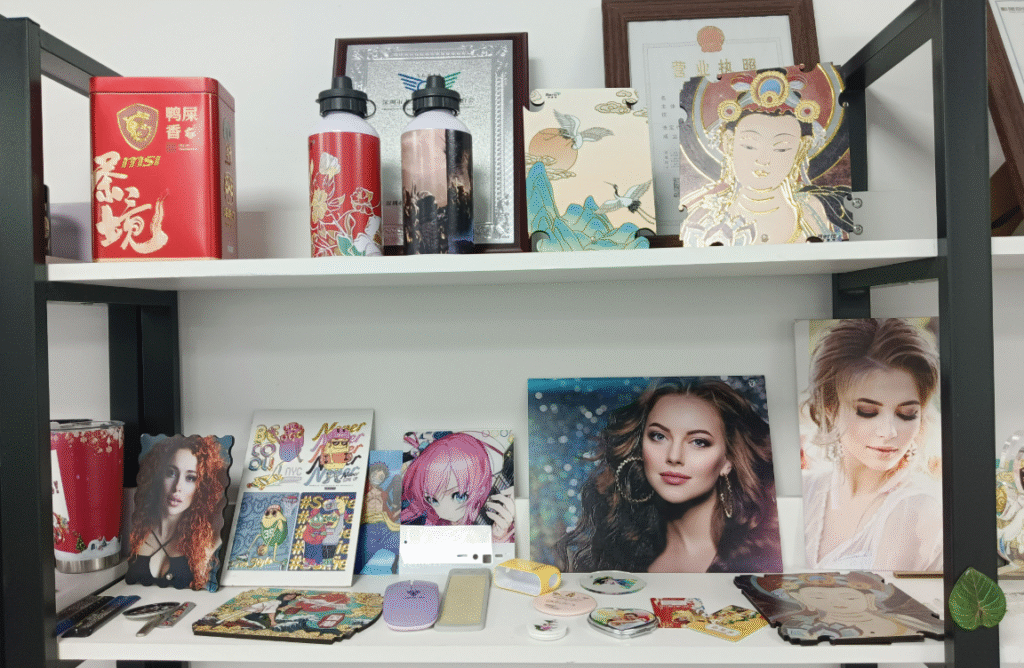

- Material versatility. You can print directly onto phone cases, acrylic signage, wooden tags, metal nameplates, and even leather accessories — no transfer paper required. This flexibility opens many product lines from one machine. subli-star.com

- Speed and durability. Instant curing means finished goods come off the bed ready to ship; prints resist scratches and wear better than some alternative methods. Colour Vistas

- Lower barrier to entry. New compact models designed for makers (including household-friendly devices) are bringing UV printing into studios and small shops, not just factories. This shift is expanding who can produce high-quality, textured, or raised prints at reasonable cost. The Verge

These advantages make UV printing especially attractive for phone case printing, on-demand merch, and custom tech accessories — product categories that are trending with younger buyers who value uniqueness. mtutech.comaikusu.com

UV printing vs. sublimation (and when to pick each)

If you’re researching printing methods, you’ll often see UV printing compared to dye-sublimation and direct-to-garment (DTG) processes. Here’s a simple breakdown:

- UV printing: Best for rigid substrates (plastic phone cases, metal, wood, glass). Produces crisp detail, works on many materials, and gives scratch-resistant prints. Colour Vistas

- Sublimation: Ideal for polyester textiles and specially coated substrates; the dye becomes part of the material, so prints are soft and washable (great for apparel, soft signage). 40 Visualsagoodprinter.com

- DTG/DTF: Best for full-color prints on cotton or transfer workflows; different strengths and ink requirements.

Practical rule: choose UV when your products are rigid or require a glossy/raised/3D texture finish; choose sublimation for fabric and wash-proof apparel.

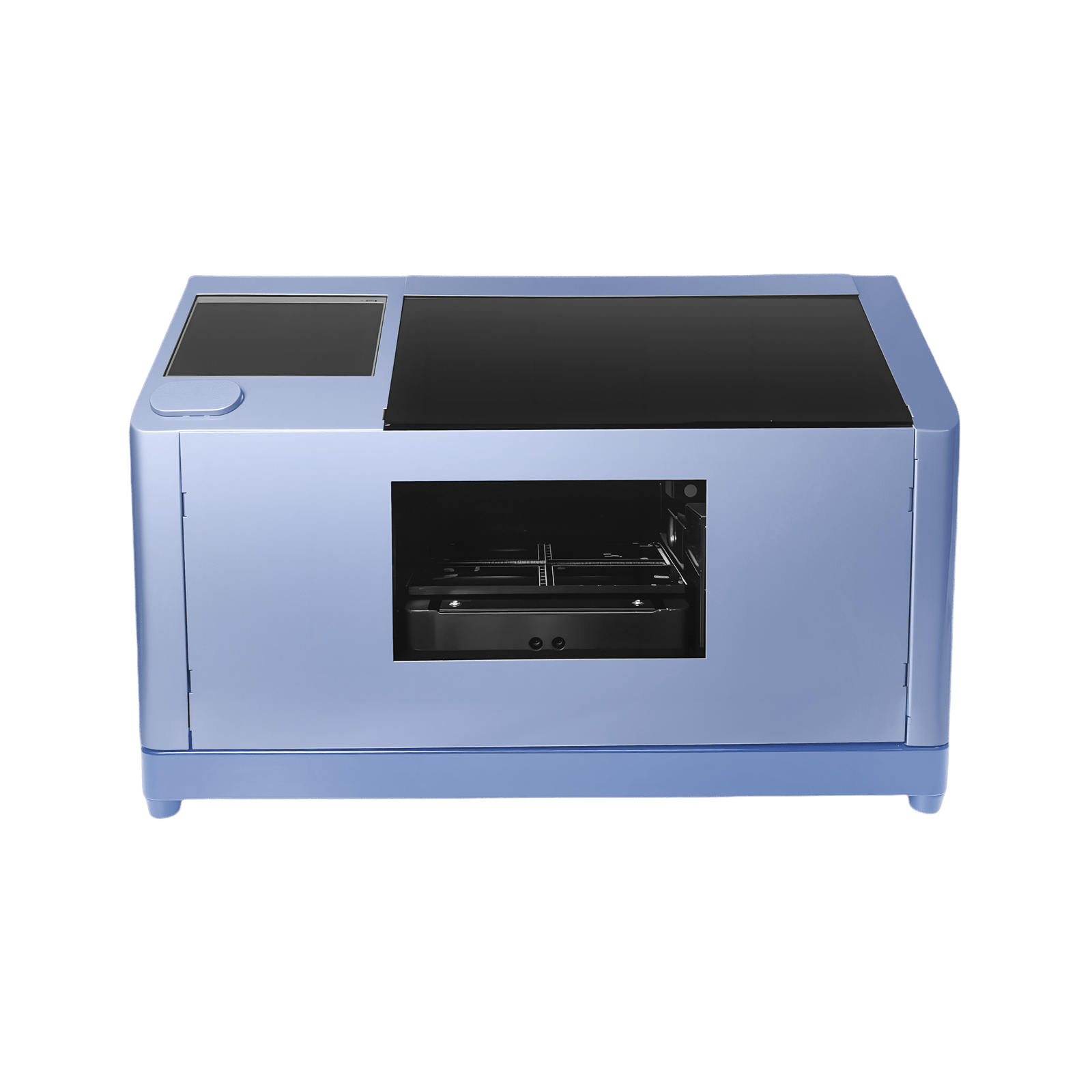

Why A5 and small flatbed UV printers matter for small businesses

Large industrial flatbeds are powerful but expensive and space-consuming. The recent surge in A5 UV printers and compact flatbed models is significant because these machines let small shops print phone cases, small signage, coasters, and personal items with commercial quality while keeping costs and footprint low. Models designed specifically for phone-case printing often include jigs and fixtures (so you don’t need to measure each case manually), and some include automatic height-sensing to protect print heads and improve accuracy. These features make launching a profitable micro-printing business much more feasible. erasmart.comProcolored

The workflow: how a modern UV printing setup actually works

A typical efficient workflow for small-batch production looks like this:

- Design: Create or receive a customer’s artwork (PNG, JPEG, vector).

- Preflight: Resize and position the artwork using the printer’s RIP or mobile app.

- Fixture & measure: Place the item in a jig or on the bed; many modern units use infrared or camera-based sensors to set the print height automatically. erasmart.comThe Verge

- Print & cure: The printer lays ink and UV lights cure it instantly.

- Finishing: If needed, apply a protective coating or perform minimal post-processing.

- Ship/sell: Ready-to-ship items reach customers quickly thanks to instant curing and minimal drying time.

If your machine supports a mobile app or cloud workflow, steps 1–3 can be drastically simplified: upload, preview, and print from a smartphone — a huge time-saver for shops that want speed and customer-facing convenience.

10 product ideas you can make and sell with a UV printer

- Custom phone cases and tech covers (high demand from Gen Z and gifting). mtutech.com

- Personalized metal keychains and tags.

- Branded acrylic signage for local stores or events.

- Customized wooden coasters and home décor.

- Leather luggage tags and small accessories.

- Promotional items: bottle openers, power bank shells, and more.

- Corporate giveaways with logo printing.

- Small-run product prototypes and mockups.

- Wedding and event favors with names/dates.

- Limited-edition merchandise with textured finishes.

These categories combine impulse gifting and repeat business — great for online stores, marketplaces, and local retail.

Marketing tips to sell more UV-printed items

- Feature “real-life” mockups. Show phone cases and accessories on real people — lifestyle photos sell better than flat product shots.

- Offer fast personalization. “Print & ship in 24–48 hours” converts visitors who want quick gifts.

- Bundle and upsell. Offer a case + charger pad combo, or print-on-demand bundles for events.

- Promote textured finishes. Raised or glossy inks are tactile selling points many competitors don’t highlight.

- Leverage social proof. Share customer photos and short clips of the printing process (videos of the item coming off the bed look great on Instagram).

- Target niche communities. Gamers, pet owners, and wedding planners all respond well to personalized products.

These strategies pair especially well with on-demand manufacturing: keep inventory low, test designs quickly, and scale what sells.

Buying guide: what to look for in a compact UV printer

When evaluating small UV printers, consider:

- Substrate support: Will it print on the materials you want—plastic, leather, metal, wood, or glass? subli-star.com

- Print size and resolution: A5 beds suit phone cases and small items; larger beds are needed for signage.

- Height detection & fixtures: Automatic sensors and quality jigs save time and reduce errors. erasmart.com

- Ink costs & availability: Check cartridge sizes, replacement costs, and lead times.

- Software & connectivity: Mobile app control and Windows/Mac RIP compatibility streamline production.

- Warranty & support: Fast technical support and spare-part availability matter for uninterrupted operations.

Choosing the right machine is a balance of budget, planned products, and expected throughput.

Common questions (quick answers)

Is UV printing safe? Modern UV inks and machines follow industry safety standards, but always follow the manufacturer’s ventilation and handling recommendations.

Can I print multi-color gradients and photos? Yes—UV printers can reproduce complex color images with high detail. Colour Vistas

Do UV prints wash or scratch off? Cured UV inks are highly durable and more scratch-resistant than many solvent-based prints, making them suitable for items handled frequently. Colour Vistas

Final thoughts: where the market is heading

The market for personalized tech accessories and small-run custom merchandise continues to grow, fueled by consumer demand for unique, expressive products. Compact, user-friendly UV printers — especially those that bring app-driven workflows and automatic sensing to the table — are lowering the entry barrier for makers and small businesses. Recent product launches aimed at home and studio users suggest that UV printing will get even more accessible and creative in the near future. If you’re selling custom phone cases, branded gifts, or on-demand merch, UV printing is worth strong consideration.